The Pressure is on to Reduce the Cost of Corrosion, Increase Readiness and Reduce Maintenance Costs.

THE ISSUE:

Unprotected equipment outside is deteriorating; water intrusion, mold, UV, corrosion. Corrosion impairs the readiness of military armament. The Army reported a significant number of failures due to corrosion on the 155 mm medium-towed howitzer so severe that they resulted in aborted missions. A study estimates that between 30 to 40 percent of the aborts are direct results of corrosion. Corrosion is also identified as accounting for 39 percent of all unscheduled maintenance for the howitzer, further reducing the readiness levels of the equipment.** Corrosion Cost for Army Ground Vehicles is 12.6 percent of the total maintenance costs for all Army Ground Vehicles.* Corrosion accounts for 8% of weapons down-time or instances wherein they do not function properly.

Army Vehicles with the Highest Average per Vehicle and Total Corrosion-Related Cost*

| LIN | Description | Average corrosion-related cost per vehicle (thousands) | Rank in top 20 of corrosion related cost per vehicle | Total corrosion related cost (thousands) | Rank in top -20 of total corrosion related cost | Combined average and total cost ranking |

|---|---|---|---|---|---|---|

| T13168 | Tank Combat Full Tracked 120mm gun M1A1 | 98 | 3 | 128984 | 2 | 5 |

| T13305 | Tank Combat Full Tracked 120mm gun M1A2 | 134 | 2 | 62581 | 3 | 5 |

| H57642 | Howitzer Medium Self Propelled | 50 | 7 | 34309 | 5 | 12 |

| F40375 | Fighting Vehicle Full Tracked Industry Hi Survivability | 22 | 13 | 32229 | 6 | 19 |

| R50681 | Recovery Vehicle Full Tracked Medium | 19 | 14 | 21397 | 9 | 23 |

| G78306 | Generator Set Diesel 60Kw50/60Hz-Trailer Mounted | 32 | 9 | 13884 | 15 | 24 |

| T96883 | Trailer Flatbed 5 Ton 4-Wheel General Purpose | 12 | 19 | 25753 | 8 | 27 |

| YF200R | Mine Resistant Vehicle Cart 1 | 26 | 11 | 10704 | 18 | 29 |

THE SOLUTION:

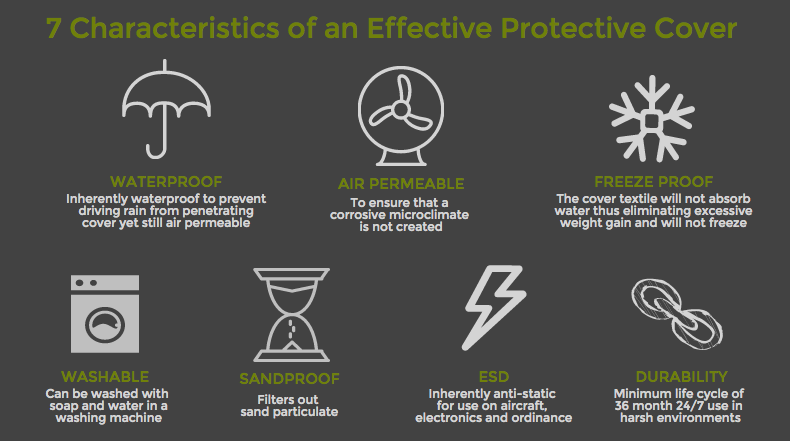

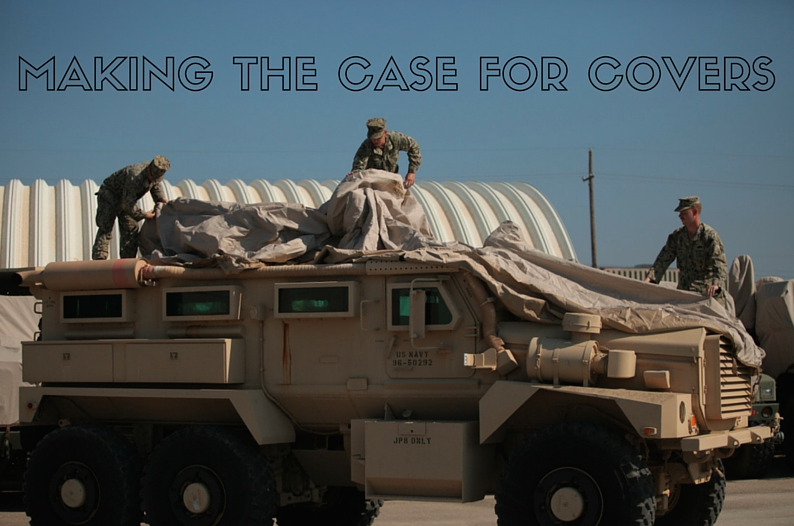

Protective Covers. Almost all vehicles that have turrets leak have the following issues: internal mold and corrosion, coating system deterioration due to UV and abrasion, equipment electronic failure from corrosion and excessive heat damage during storage, airborne particulates which cause corrosion and sand damage to windscreens. Protective covers are having a dramatic effect in reducing corrosion from UV, sand, moisture and airborne pollutants. To be effective a cover needs, at a minimum, to be extremely air permeable to naturally offload moisture and heat. The US Army is having success using special corrosion-reducing covers. An effective protective cover, employed correctly, will significantly improve readiness, reduce maintenance and extend life cycle. “Corrosion remains the largest preventable cost to the U.S. military, a cost which exceeds $23.0 billion per year.” Heat, dust, UV rays and moisture degrade military hardware, leading to decreased readiness, increased manpower requirements and significantly higher long-term costs.

When Selecting A Protective Cover For Your Equipment, Ask the Tough Questions.

DURABILITY:

- Is the Cover Hydrophobic, so that it will not absorb water or freeze?

- Is the Cover Oleophobic so that it will not absorb fuel and lubricants?

- Will the Cover filter out the fine sand, dust and pollution found in theatre?

- Does the cover eliminate the destructive “greenhouse effect” in both short and long term use?

SCIENCE:

- Is the Cover lightweight, easy to pack and does it require minimal storage space?

- Can the Cover be easily cleaned in a washing machine or with soap and water in the field?

- Will the Cover prevent scratches to wind-screens and lenses and reduce paint wear?

- Can tears and rips to the cover be easily repaired in the field?

USABILITY:

- Will the Cover withstand ultraviolet ray (UV) exposure for at least 36 months of 24/7 use?

- Is the fabric durable enough to sustain rough handling after hundreds of uses?

- Will the Cover maintain its effectiveness?

For more information about the benefits and cost savings of adopting covers into your equipment lifecycle management program, contact your ADS Representative or Cocoon Inc.

REFRENCES: *Reference : CorrDefense Volume 9, Number 1 Spring 2013 Inside DOD: DOD estimates the Effect of Corrosion on the Cost and Availability of Army Ground Vehicles **Reference: GAO-03-753

ABOUT COCOON Cocoon, Inc. is dedicated to protecting mission critical assets from the elements by way of innovative Protective Covers, Corrosion Free Storage, Fabric Hangars that are specialty engineered and built to code and Warehouses. To learn more about Cocoon, please visit our website at www.cocoon-inc.com

ABOUT ADS ADS Inc. is a leading solutions provider that proudly serves all branches of the U.S. Military, federal, state and local government organizations, law enforcement agencies, first responders, partner nations and the defense industry. The weapons and optics team at ADS understands the importance of having access to critical components and equipment required to effectively maintain, upgrade and secure military commands’ weapon systems. This latest contract is another demonstration of ADS’ ability to integrate partner capabilities to best serve its customers. Overall, ADS is focused on solving customers’ challenges through the largest product and service offerings, the broadest array of procurement and contract options, world-class support and logistics solutions and legendary customer service. To learn more, please visit the ADS website at www.adsinc.gurumediadev.com.