CUSTOMER PROFILE:

National Guard Unit

This particular unit of the Army National Guard is comprised of part-time citizen soldiers tasked to function as more of an operational force than a reserve. Best described as innovative, this unit is known for conducting extensive research on solutions to long-term problems and have worked with ADS over the last 3 years to implement BERG expandable and non-expandable shelter systems.

THE CHALLENGE:

Expensive and Time-Intensive Medical Care

The customer acknowledged that their existing plan to meet the requirements of their annual Periodic Health Assessment (PHA) were both expensive and inefficient. While this unit had medics trained in PHA standards and protocols, they were outsourcing medical and dental care services to contractors and civilian groups. In addition to paying for services they could provide with existing resources, some of the care facilities were not local, requiring soldiers to incur extended time out of the office and travel-related expenses to attend their PHA-related appointments.

THE PROPOSED SOLUTION:

A Purpose-Built, Portable Care Solution

BERG shelter systems offer customers the perfect blend of flexibility and capability as a mobile, towable and transportable self-sustaining operational space. Their basic non-expandable, Conex-based shelter systems are available in a variety of sizes. For those looking for a more dynamic solution, BERG also offers their E2S2 line of expandable shelter systems.

Both shelter systems are highly portable, can be loaded and offloaded by forklift or crane, and can be transported by flatbed or Palletized Load System (PLS). They also can be set up by two people in 15 minutes or less, allowing for soldiers to grow their skill sets and increase readiness more efficiently, saving both time and resources. Finally, BERG and ADS can work with customers to tailor any of their shelter systems with specific workspace, storage, equipment and supply configurations while adhering to DoD engineering and safety equipment regulations — creating a true mission-driven solution.

As it pertains to state rules and requirements, BERG shelter systems are considered a mobile structure (rather than a fixed structure), which in this instance, provided some much-needed budgetary flexibility. Since the shelter is self-deploying and can be set up by two people in 15 minutes or less it allows for soldiers to grow their skill sets and increase readiness more efficiently, saving both time and resources

By adopting a mixture of expandable and non-expandable BERG shelter systems, customers can achieve additional capability to meet concurrent readiness demands, including medical, dental, hearing, administration, operations and classroom training.

THE RESULT:

Increased Mission Readiness and Decreased Costs

After reviewing procedures and time spent in accomplishing medical, hearing and dental readiness requirements, the National Guard customer invested in eight customized BERG E2S2 expandable shelters and four 20’ Conex non-expandable shelters systems, each designed to provide care to 500+ soldiers. Of the eight E2S2s, two were outfitted to conduct PHAs, two for dental exams, and three for Administration & Operations. All four of the 20’ Conex shelter systems were dedicated to administering hearing tests.

Once ADS, BERG and the customer worked through product development, the customer elected to purchase them through the Defense Logistics Agency’s (DLA) Tailored Logistics Support Program (TLSP) contract. This IDIQ contract is scope-driven, simple to use, quick from submission to award, and accepts MILSTRIPs and MIPRs. For this requirement, the approval of funds and award through the TLSP contract took 30-45 days, and the solutions were produced and delivered to the customer within 60-90 days.

Every brigade in the National Guard has a Brigade Support Battalion (BSB) that supports Basic Combat Training (BCT). The addition of BERG shelter systems enabled this unit’s BSB to provide field maintenance and medical support more efficiently throughout training exercises without interruption to training while reducing overall costs.

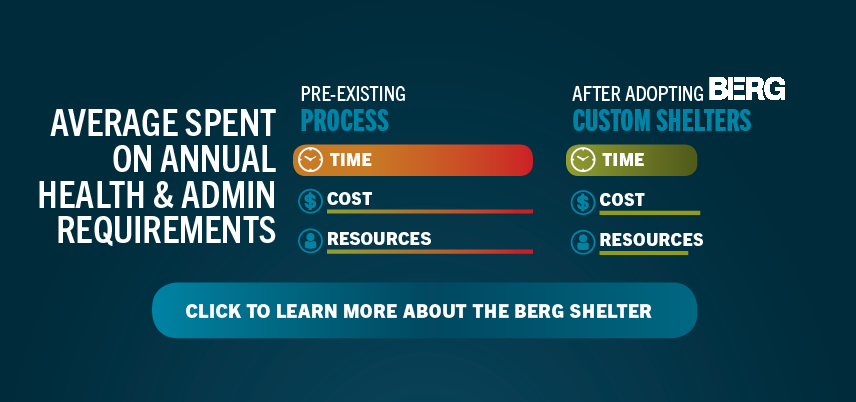

In conclusion, the adoption of the BERG purpose-built expandable and non-expandable shelter systems resulted in tremendous cost, time and resource savings, as well as increased efficiency in skill set development and additional budgetary funds to invest in medical and dental requirements for the National Guard soldiers.

For more information on BERG shelter systems or other customized solutions to support your mission, contact a knowledgeable ADS Representative at 866-845-3012 or fill out the information form below and we will be in touch with you within 1 business day.

ADS Inc. is a leading value-added logistics and supply chain solutions provider that proudly serves all branches of the U.S. Military, federal, state and local government organizations, law enforcement agencies, first responders, partner nations and the defense industry. ADS is a Top 50 Department of Defense Contractor and Gold Tier supplier for the Defense Logistics Agency. The company is focused on solving customers’ challenges by providing the best product and service offerings, the broadest array of procurement and contract options, world-class support and legendary customer service.